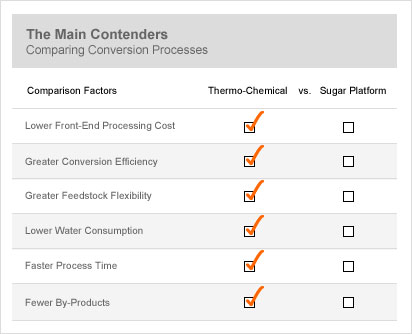

Face Off: Producing Cellulosic Ethanol:

Sugar Platform Vs. Thermo-Chemical

There are two ways to convert biomass to cellulosic ethanol: sugar platform and thermo-chemical conversion processes.

The Contenders

The first process, which uses acids or enzymes, converts a portion of the biomass to simple sugars that are fermented and converted into ethanol. These methods are lumped together under the label “sugar platform.” Thermo-chemical processes use chemical reactions to convert all of the biomass to a gas that is transformed into a variety of substances, including ethanol. Some hybrid processes are also under development to combine parts of each method.

Sugar-Platform Processes

All sugar-platform processes use biological organisms, such as yeasts, that consume simple sugars and excrete ethanol. Like all biological organisms, they have a preferred “food” and a preferred environment that keeps them healthy. The yeasts that convert simple sugars to ethanol have been understood and used in making beer, wine, and liquor for millennia.

The search is on to find or to create organisms that can break down the components of biomass called cellulose, hemicellulose, and lignin into simple sugars. While “designer” enzymes have been developed to break down cellulose and hemicellulose into simple sugars, breaking down the lignin has been more difficult. Most sugar-platform processes assume that the lignin will be used to fuel the ethanol-making process. The final step in producing ethanol includes separation and concentration (fractionation and distillation) prior to use in blending with gasoline.

Thermo-Chemical Processes

Thermo-chemical processes use various combinations of temperature, pressure, residence time, water, oxygen or air, and catalysts to convert biomass to cellulosic ethanol. These processes transform all of the non-mineral constituents of the biomass into a common form – synthesis gas or syngas. The syngas is passed over a catalyst, which acts much like the catalytic converters used in automobiles, and converts it into ethanol and other alcohols. As with the sugar-platform process, the final step includes separation and concentration.

Besides producing ethanol and other alcohols, the syngas can be used to produce synthetic petroleum products, fertilizer, plastics, and many other products. It can also be used as a fuel to generate electricity.

Round 1: Cost Comparison

Production costs for all early-stage cellulosic ethanol processes can be assumed to be much higher than will ultimately be achievable, but some general observations can be made. Sugar-platform cellulosic ethanol processes can be viewed as a front-end or pre-treatment for existing fermentation processes used today to make ethanol. The additional cost of this front-end step must be fully offset by the savings provided from using a much lower cost feedstock. The major, critical cost component in the front-end step is assumed to be the enzymes used to break down a portion of the biomass into simple sugars. Efforts are under way to dramatically reduce enzyme costs to bring overall costs in line with competing processes.

Thermo-chemical processes consume energy and use expensive materials to withstand the temperatures and pressures necessary to convert the biomass into cellulosic ethanol. To reduce production costs, focus will be placed on advances in materials design and process efficiency.

Round 2: Efficiency Comparison

Considerable efficiency gains for both processes are expected as commercial experience is obtained, but the areas targeted for gains are quite different. Sugar-platform efficiency gains could benefit considerably from finding a way to convert a greater part of the feedstock to ethanol. The fact that a significant portion of the biomass feedstock, lignin, is being considered for gasification to fuel the process of making ethanol demonstrates this fact best.

Thermo-chemical platforms gain most from reducing temperatures and pressures needed to convert the biomass. This reduces the need for expensive materials or fabrication techniques. A strength of thermo-chemical processes is that they convert all of the biomass, except minerals. As a result, any net gains from reduced energy consumption and process efficiency directly increase ethanol production as less of the biomass is used to power the process.

Round 3: Flexibility Comparison

Flexibility addresses each platform’s tolerance for variations in biomass type and quality. The enzymes used in converting biomass to cellulosic ethanol tend to be highly specialized. Although work is under way to produce more tolerant and flexible enzymes, the present biological organisms are fairly picky, making it difficult for them to tolerate significant variations in biomass feedstock quality, not to mention their ability to process multiple feedstocks.

The thermo-chemical process employed by Range Fuels has successfully converted a wide range of feedstocks during testing. It also has a much higher tolerance for inconsistencies in sizing and moisture content than any competing process. This flexibility is expected to provide greater reliability and more consistent production in commercial installations.

Round 4: Water Usage Comparison

An important difference between sugar-platform and thermo-chemical processes relates to the amount of water used in each process. Sugar-platform processes typically quote water usage of 4-5 gallons for each gallon of ethanol produced. There are variations between thermo-chemical processes, but most designs project water usage of only 25 percent to 50 percent of that needed for sugar-platform processes.

Round 5: By-Product Comparison

Sugar-platform cellulosic ethanol processes produce a significant amount of lignin as a by-product. Range Fuels’ two-step thermo-chemical process produces very little waste or by-products. The mineral constituents contained in the feedstock and a small amount of unreacted carbon are left over from Range Fuels’ process. Work is under way to assess the value of this material for land application and restoring minerals to the soil. A distinguishing feature of Range Fuels’ process is that it produces low amounts of tars, which is not always the case with other thermo-chemical processes.

Round 6: Process Time Comparison

Sugar-platform processes take several days to convert the biomass to cellulosic ethanol, largely as a result of the time needed for fermentation. Range Fuels’ thermo-chemical process can convert biomass into fuel-grade ethanol in less than an hour.